Pavlodar Oil Chemistry Refinery LLP received an Environmental Impact Permit for Category I facilities No. KZ15VCZ03216544 dated April 10, 2023 (hereinafter referred to as the Environmental Permit).

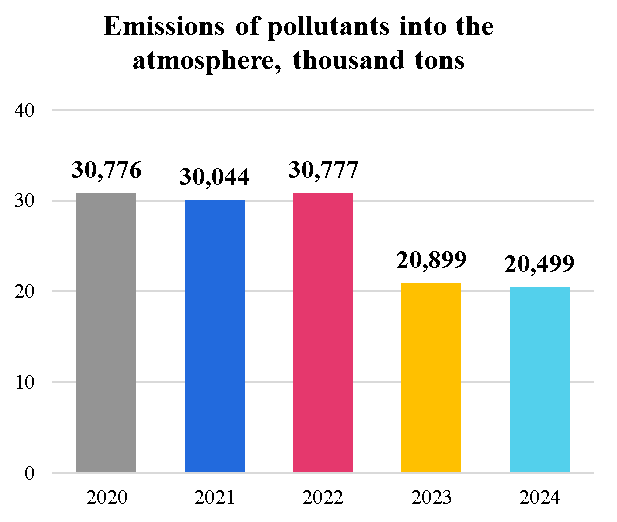

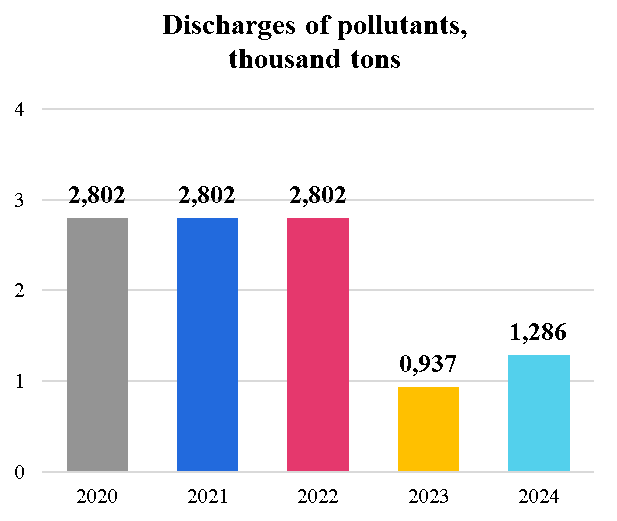

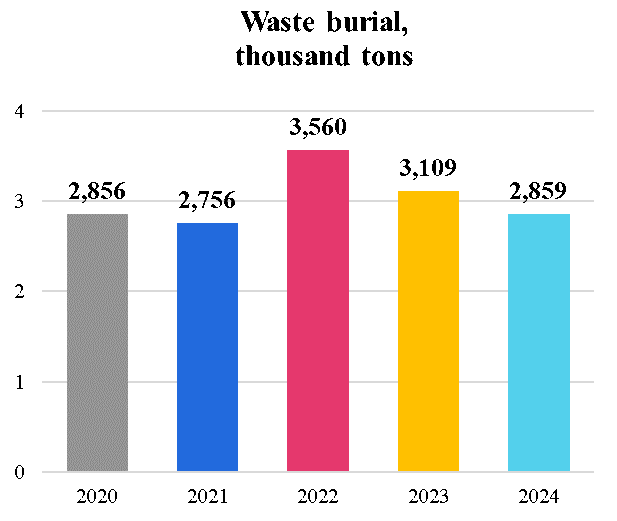

The environmental permit for Pavlodar Oil Chemistry Refinery LLP for 2023 - 2024 sets the following standards:

| Year | Standards, tons | |||

|---|---|---|---|---|

| emissions pollutants into atmospheric air | discharges pollutants to the storage device "Sarymsak " | waste disposal | waste accumulation | |

| 2023 | 20,899.15697 | 937.07402 | 3 109.16000 | 70 605.35143 |

| 2024 | 20 499.32915 | 1,285.98762 | 2 859.23000 | 60 710.93720 |

The environmental permit includes emission standards, waste accumulation and disposal limits for the following facilities of Pavlodar Oil Chemistry Refinery LLP:

-petrochemical plant (industrial site);

-solid waste storage facility (landfill);

-wastewater storage tank “Sarymsak”;

-service organizations operating on the territory of the enterprise.

The environmental permit applies to the planned activities of Pavlodar Oil Chemistry Refinery LLP:

-implementation of a modern automation system for compressors ПК-301, ПК-302, ПК-303, ПК-304, ЦК-201, ЦК-301 of gas compressor room of Primary Crude Oil Distillation Unit;

-replacement of compressors K-2, K-3, K-4, K-5 of vacuum-compressor station of Stem-Air Supply workshop;

-changing the cooling system of pumping equipment using coolant with low corrosive activity in a closed circuit at sections C-100, C-200, C-300, C-400 of Primary Crude Oil Distillation Unit;

-major repairs of railway tracks No. 16, No. 23 and No. 28;

-major repairs of railway tracks No. 22 and No. 22A;

-major repairs of railway tracks No. 26 and No. 27 and railway track No. 2;

-modernization of instrumentation devices and implementation of the DeltaV automation system;

-modernization of the process flow cooling system by installing a VFD;

-equipping a stationary system for monitoring the technical condition of equipment at Sulfur Production No. 5;

-re-equipment of tanks P-1 and P-2 of park 29-3;

-reconstruction of deep oil refining production;

-reconstruction of the automatic fire alarm system and automatic fire extinguishing of the commodity and raw materials park;

-reconstruction of the S840 sulfur granulation plant for sulfur production;

-construction of a checkpoint for entry/exit of service company employees;

-construction of a furnace for the production of bitumen for the processing of heavy oil residues;

-construction of a wastewater filtration station after the first biological treatment system;

-construction of an LPG purification plant;

-technical re-equipment of automated process control systems of Primary Crude Oil Distillation Unit (LK-6U) and Deep Crude Oil Processing Unit;

-technical re-equipment of technological furnaces LK-6U and KT-1;

-technical re-equipment of electric dehydrators ЭГ-160 of the ELOU unit;

-installation of an automated emissions monitoring system;

-installation of new wet gas compressors at compressor KT-1 Deep Crude Oil Processing Unit.