"Pavlodar Oil Chemistry Refinery" LLP pays great attention to safety of its employees. The mainstream of labor protection is preventive and technical means necessary for safe performance of works. Prevention of occupational safety is carried out in accordance with the “Occupational Health and Safety Management System" (OHSMS).

"Pavlodar Oil Chemistry Refinery" LLP pays great attention to safety of its employees. The mainstream of labor protection is preventive and technical means necessary for safe performance of works. Prevention of occupational safety is carried out in accordance with the “Occupational Health and Safety Management System" (OHSMS).

In 2010 the Refinery Management decided to introduce “5S” System. “5S” System is a method of organizing the working space, the purpose of which is to create optimal conditions for operations performance, maintenance of order, cleanliness, accuracy, saving of time and energy. Today “5S” system effectively works at the refinery and greatly facilitates the inspection of the working conditions on workplaces.

In 2010 the Refinery Management decided to introduce “5S” System. “5S” System is a method of organizing the working space, the purpose of which is to create optimal conditions for operations performance, maintenance of order, cleanliness, accuracy, saving of time and energy. Today “5S” system effectively works at the refinery and greatly facilitates the inspection of the working conditions on workplaces.

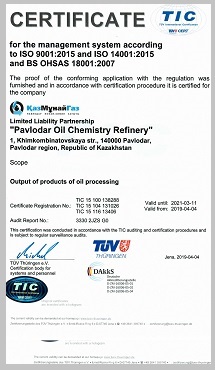

Together with compliance with the government regulations, the Refinery put a goal to comply with international safety requirements. At the end POCR LLP successfully completed conformity examination certification of Integrated Management System of the enterprise to international standards: ISO 9001:2008 (Quality Management System), ISO 14001:2004 (Environmental Management System), OHSAS 18001: 2007 (Occupational Health and Safety Management System), SA8000:2008 (Social Responsibility), ISO 50001:2011 (Energy Management). In order to increase the effectiveness of prevention of accidents, industrial injuries of workers on the enterprise it was carried out the identification and evaluation of hazards, developed measures to reduce significant risks. Also, one of the trends in occupational safety management system of POCR LLP are special requirements now imposed on contractors to ensure compliance with safety regulations and labor protection, industrial safety.

Observance of labor rights:

In 2017 POCR LLP became the owner of “Certificate of Trust” in the frames of a pilot project on participation of enterprises in the Republic of Kazakhstan in voluntary declaration of activities on observance of the labor rights of workers, and for 3 years the Refinery will be exempt from inspections by labor inspections to comply with labor legislation, as well as the enterprise is included in the Registry of employers who guaranteed respect the rights of workers.

On June 1, 2015 it was completed assessment of production facilities and work places of POCR LLP on working conditions, conducted by Kazakhstan Project - Research Institute “Kazakhstanproyekt” LLP.

According to the results of assessment there was developed an action plan for improvement and enhancement of working conditions on POCR LLP, there were set surcharges as per working conditions, additional annual paid labour vacations.

Labour Department of Pavlodar region from the 14th till 21st

of April 2016 held a competition dedicated to the World Day of Occupational Health and Safety on three nominations: The best enterprise, The best service/department, The best Engineer on Occupational Health and Safety.

According to the results of the competition POCR LLP was recognized as the best company in Pavlodar region in the area of Occupational Health and Safety.

Integrated system on Occupational Health and Safety “Aman”

At the present time it is being performed implementation of “Aman”, integrated system for labor protection.

One of the main tasks of “Aman” system is involvement of all employees of the enterprise in the processes of safety and labor protection, as well as raising the level of safety culture at the place of production.

Formation of an effective OSH management system integrated into overall management system of the company leads to higher productivity and profitability of the enterprise, lower costs and positively influences the motivation of employees. A well-developed safety culture helps to reduce costs significantly, at that creating more productive job climate, to increase efficiency, improve the company's image and provide additional financial and competitive advantages.

Perfection of safety culture means not only eliminating potential hazards at the workplace and fixing the basic rules in the form of standards and procedures, it also means a serious work with people, change of their attitude to security matters.

Well-developed safety culture provides many different advantages. Employees become more committed to work, both emotionally and physically. The turnover of staff decreases, the efficiency and quality of their work increase.

For years, HSE was seen as a regulatory obligation to meet government requirements. It was governed by, and managed in reaction to, rules and regulations. Control and discipline were prevalent. An incident-free workplace was generally not considered possible, and when it was considered, it was only a vision, at best.

Over time, our safety culture began to change as operational processes and complexity became better understood and a commitment to safety became more personal and individual. We have experienced a further evolution whereby a stronger focus on cooperation within and among team members began to see themselves as Safety Leaders. HSE became recognized as “the right thing to do” for two very important reasons (1) It is part of our moral and ethical responsibility to our employees, contractors and the communities, and (2) It is good for our business as there is no downside to good HSE practices. Conversely, the cost of poor HSE practices can be devastating to our business.

A Perfect Safety Day is when all KMG employees go home safe to their families at the end of the day: no work-related injuries or illnesses, no accidents and no damage to the environment. In 2014, the year we started tracking this number, we recorded 90 Perfect Safety Days. The number increased to 96 the following year, then soared 30% to 125 in 2017. Already this year, we are achieving them at a pace that will put us near 200 by year end. While this is remarkable, we have more room for improvement. The closer we get to 365 perfect safety days each subsequent day will become progressively more difficult to achieve.

For this reason, we are launching our 100% HSE campaign. In the past, we have set zero incidents as a vision and a goal. Now, we are setting zero incidents, accidents and spills as an expectation. This means there are no exceptions for shortcuts, rule breaking or compromise.

My leadership team and I are committed to 100% HSE. Please ensure this message is well understand across our company.

Best Regards,

Sauat Mynbayev